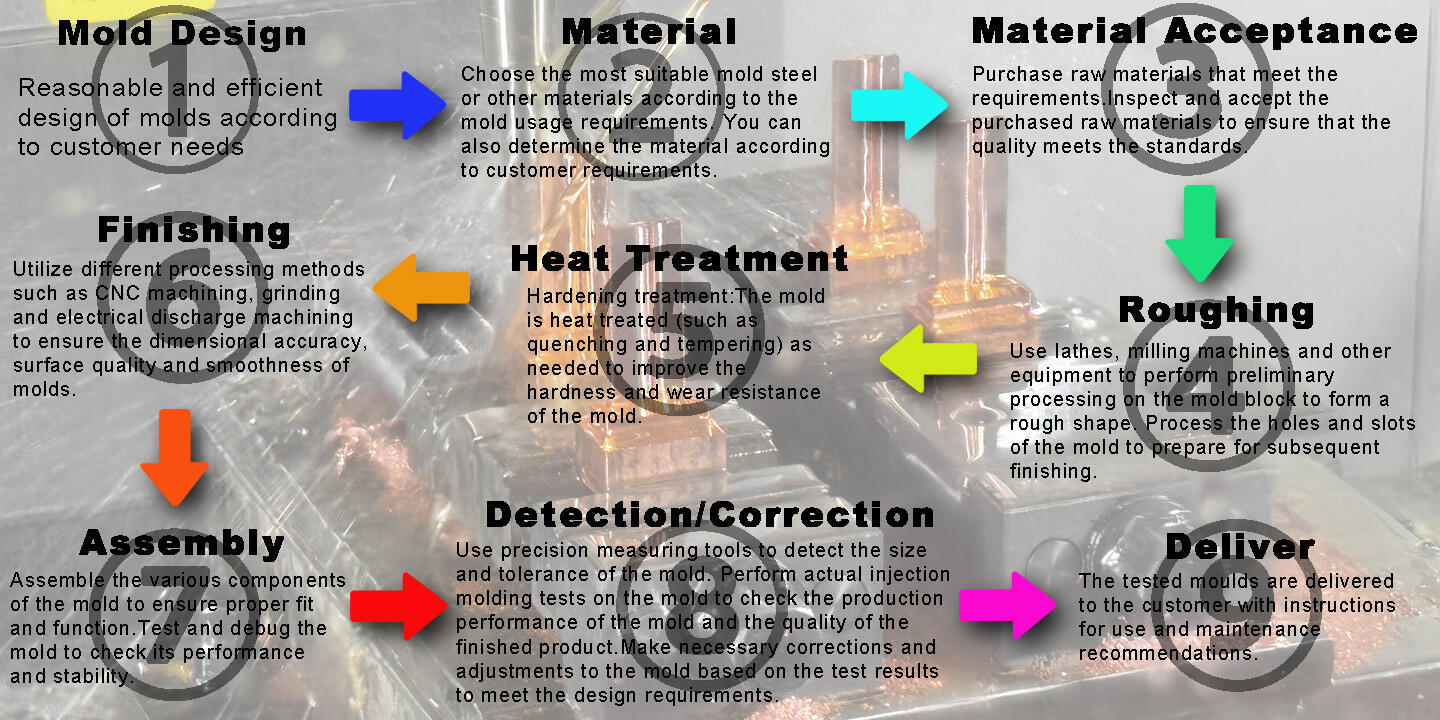

Our advanced injection molding technology possesses the capability to produce a diverse range of products. By leveraging our injection molding expertise, you can expect superior mold engineering, precision machining, and flawless mold assembly. This extensive versatility guarantees that your products will be crafted to the utmost standards of quality and craftsmanship.

Megaphos Injection Mold Manufacturing Factory is a professional manufacturer dedicated to providing customers with high-quality injection molds. We have established a good reputation in the mold manufacturing field with rich experience, advanced technology and strict quality control.

13 Years of production experience, proficient in a variety of machine tools and equipment.

8 Years of production experience, In-depth understanding of the mold manufacturing process and strict control of mold processing quality.

9 Years of production experience,Possess good communication skills and be able to work closely with team members to solve production problems.

8 Years of production experience, With many years of experience in mold production, he has participated in the manufacturing of many large or complex mold projects.

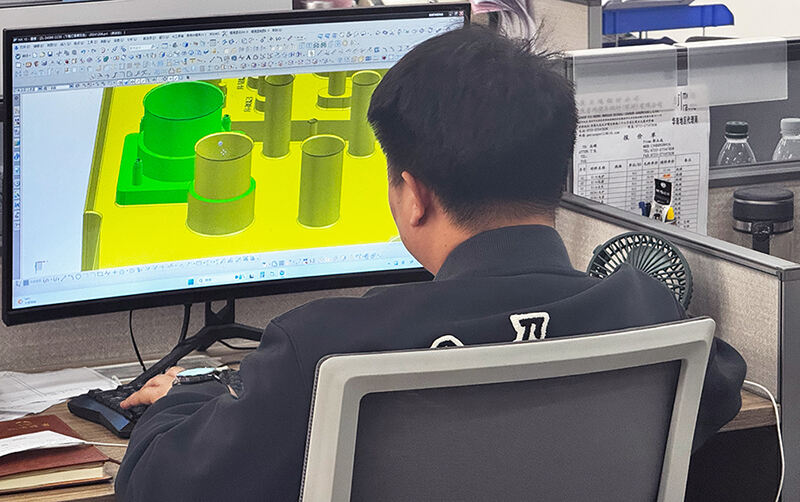

We have a professional design team composed of senior engineers and technicians. They have rich experience in mold design and can provide customized solutions according to customer needs. From preliminary design to final draft, our design team will maintain close communication with customers to ensure that the mold design meets customer expectations and requirements.

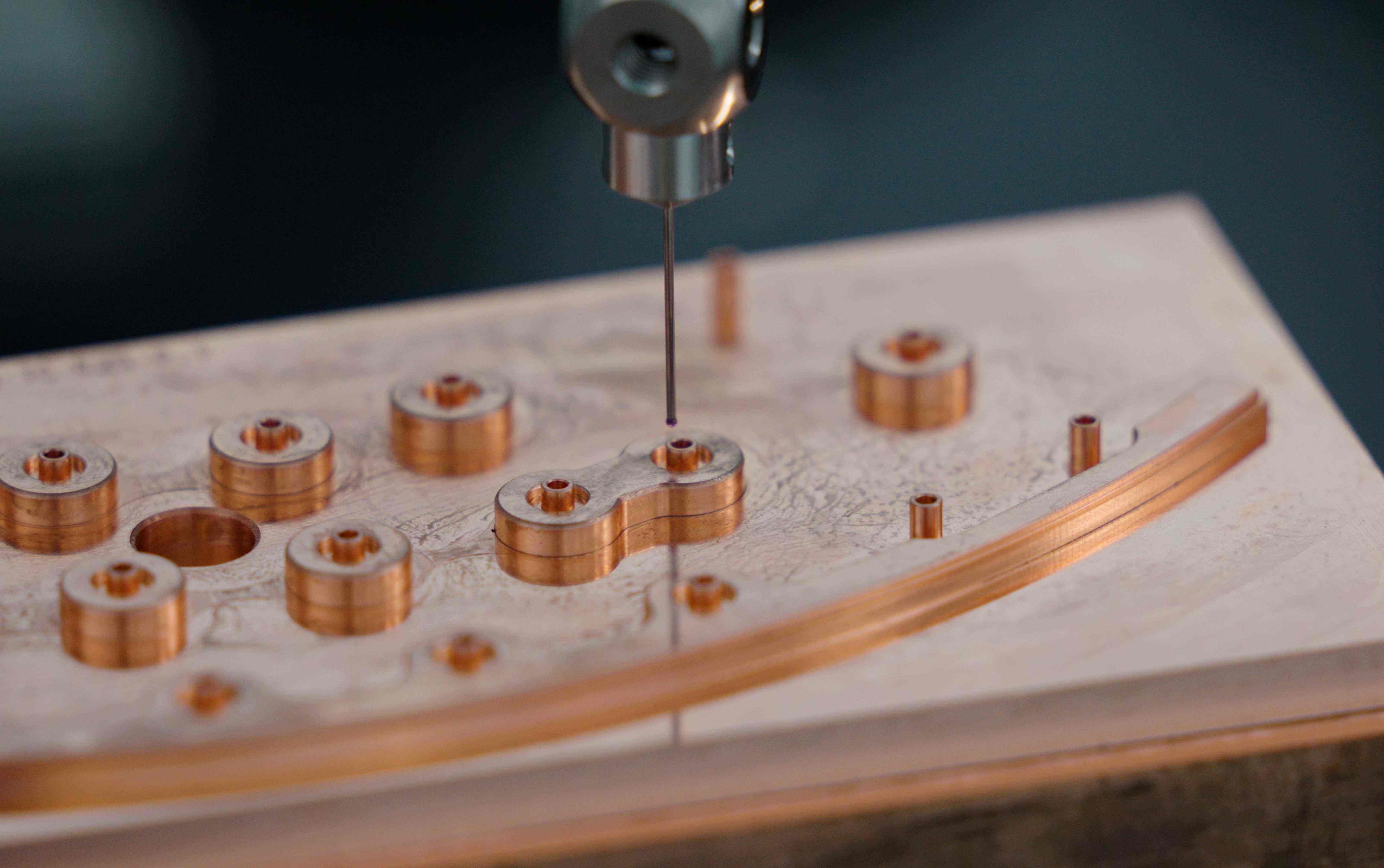

Megaphos has introduced advanced production equipment and technology, including high- precision CNC machine tools, EDM machines, wire cutting machines, etc. These equipment can ensure the accuracy and efficiency of mold processing and improve the quality and reliability of molds. At the same time, we also pay attention to the maintenance and updating of equipment to maintain the stability and efficiency of the production line.

We have established a complete quality management system and conduct strict quality control on every link of mold manufacturing. From raw material procurement to finished product delivery, we will conduct multiple inspections and tests to ensure that the mold meets the customer's standards and requirements. At the same time, we have also established a quality traceability system so that problems can be quickly located and solved when they occur.

Megaphos has many years of experience in mold manufacturing and has accumulated rich manufacturing experience and successful cases. We have provided high- quality mold manufacturing services for many industries, including medical, optical lens, automotive, electronics, home appliances, etc. These experiences enable us to better understand the needs and expectations of customers and provide customers with better mold manufacturing services.

We focus on long-term cooperation with customers and provide efficient after-sales service. During the use of the mold, if the customer encounters any problems or needs technical support, we will respond in time and provide solutions.

We know the importance of varied injection molding options in plastic injection mold makinhg. In order for products to be mass produced swiftly, industries need good quality molds.Which is why we offer multiple mold making techniques.

Insert Mold refers to a molding process where a separate, often replaceable, component or insert is used within a larger mold to create specific features or details in the molded product. This technique allows for greater flexibility and precision in molding complex designs.

Overmold refers to the process of molding a plastic or other material over an existing part or assembly, often to provide additional protection, insulation, grip, or aesthetic features. This technique can combine multiple components into a single, integrated product.

Plastic injection molding is Megaphos bread and butter. This technique allows us to makes some of the most sophisticated and robust molds in the world.

Megaphos excels in tackling the challenges of high-volume injection molding, delivering top-quality parts at mutually advantageous prices. We provide our clients with enhanced value through adaptable production alternatives, robust and enduring molds, and expert guidance. By striving to create the most dependable and efficient plastic molds, we further reduce our customers' time and cost expenditures.

The durability of the steel used significantly influences the lifespan of the mold. To uphold the Megaphos standard in all our molds, we acquire steel from reputable international brands. Furthermore, we go beyond mere procurement; upon arrival of each new steel batch, we rigorously analyze it to guarantee optimal mold quality and extended mold longevity.

At Megaphos, we will match the most suitable equipment to the required shape of the mold to achieve the best precision. Our equipment includes:

·Wire Cutting Machine

·CNC Machine

·EDM Machine

·Drilling Machine

·Grinding Machine

·Milling Machine

To ensure the accuracy of our molds, we deploy 4 High-Speed CNC machines which have a maximum operation range of 1000*650*550mm and have tolerances of 0.002mm.

During each process of mold-making, CMM coordinate measuring machine is used to inspect dimensions. Only when the dimension of each part is confirmed will it enter the next step.