Advanced Design Integration

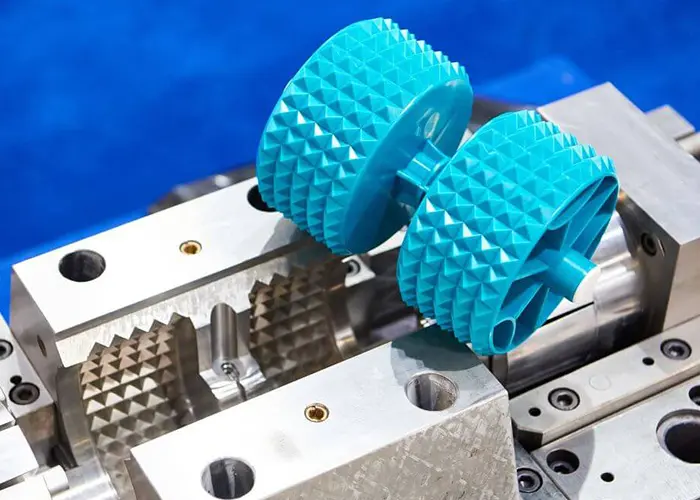

Custom molds excel through their sophisticated design integration capabilities, incorporating cutting-edge technological features that enhance production efficiency and product quality. The design process utilizes advanced simulation software to optimize material flow, predict potential issues, and ensure optimal part quality before manufacturing begins. These molds feature precisely calculated runner systems that minimize material waste while ensuring uniform filling of all cavities. The integration of conformal cooling channels, strategically positioned throughout the mold, provides superior temperature control during the molding process, resulting in reduced cycle times and improved part quality. Smart sensors embedded within the mold monitor critical parameters such as pressure, temperature, and flow rates in real-time, enabling precise process control and quality assurance.