Advanced Thermal Management System

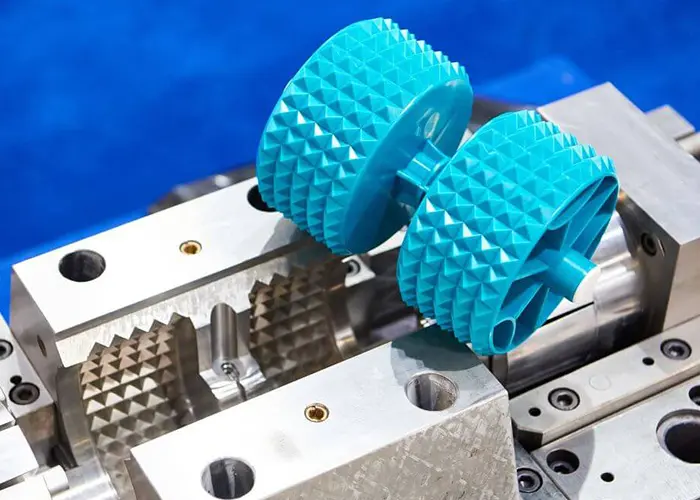

The prototype and plastic mold system features a revolutionary thermal management system that sets new standards in injection molding efficiency. This sophisticated system incorporates strategically placed cooling channels that provide uniform temperature distribution throughout the mold cavity. The precision-controlled cooling process prevents common issues such as warping and dimensional instability, ensuring consistent part quality across production runs. Advanced sensors continuously monitor and adjust temperature parameters in real-time, optimizing cycle times while maintaining product integrity. This thermal management system reduces cooling time by up to 40% compared to conventional molds, significantly improving production efficiency and reducing energy consumption.